When it comes to pushing your Ford Mustang GT to its limits on the track, maintaining optimal engine temperature is non-negotiable. Stock radiators, while adequate for daily driving, often fall short under the relentless demands of high-performance track use. Overheating can lead to catastrophic engine damage, reduced power output, and even forced pit stops—ending your race day prematurely. This guide dives deep into why upgrading to a heavy-duty aluminum radiator is critical for track enthusiasts, explores the engineering behind these performance-focused cooling systems, and provides actionable insights to help you select the best components for your build.

Why a Heavy-Duty Aluminum Radiator is Essential for Track-Ready Mustangs

The Ford Mustang GT’s 5.0L Coyote V8 engine generates immense heat during aggressive driving. On the track, where RPMs stay elevated and airflow is inconsistent (e.g., during tight corners or drafting), the factory cooling system struggles to dissipate heat efficiently. Aluminum radiators address these shortcomings with:

- Superior Thermal Conductivity: Aluminum transfers heat 4x faster than traditional copper/brass radiators.

- Lightweight Durability: TIG-welded aluminum cores resist corrosion and vibration fatigue.

- Increased Core Thickness: High-density dual- or triple-pass designs maximize coolant exposure to cooling fins.

- Custom Fitment: Direct bolt-on designs maintain OEM mounting points for hassle-free installation.

We’ll break down how these features translate to real-world performance gains and longevity for your Mustang GT.

Engineering Breakdown: What Makes a Radiator “Track-Ready”?

Not all aluminum radiators are built for the track. Here’s what to prioritize:

1. Core Design

- Dual-Pass vs. Triple-Pass: Triple-pass radiators force coolant through three separate channels, extending dwell time for better heat dissipation—ideal for endurance racing.

- Fin Density: Higher fin counts (e.g., 16 FPI) create more surface area but require robust fans to pull airflow.

2. Construction Quality

- TIG Welding: Precision welding prevents leaks under high-pressure conditions.

- Brazed vs. Epoxy Tanks: Avoid epoxy-bonded tanks, which degrade under extreme heat. Opt for fully welded aluminum end tanks.

3. Cooling Capacity

- Oversized Dimensions: A 30-40% larger core than stock increases coolant capacity.

- Integrated Oil Coolers: Some radiators include provisions for auxiliary oil coolers, centralizing your cooling setup.

4. Compatibility

- Factory Fans and Shrouds: Ensure the radiator supports OEM or upgraded electric fans for seamless integration.

- Transmission Lines: Automatic Mustangs require transmission cooler fittings.

Top Heavy-Duty Aluminum Radiators for Ford Mustang GT Track Use

Below are industry-leading radiators designed to withstand track abuse. Each is compatible with 2015+ S550 and 2018+ S650 Mustang GTs unless noted:

- Mishimoto Performance Aluminum Radiator

- Fully TIG-welded, 42mm core.

- CNC-machined bungs for aftermarket temperature sensors.

- Lifetime warranty against defects.

- CSF Racing Triple-Pass Radiator

- 3-row hyper-core technology.

- Direct fitment with factory active grille shutters.

- Koyorad High-Capacity Aluminum Radiator

- Laser-welded core with reinforced mounting points.

- Compatible with factory coolant overflow tanks.

- CSF RADIATOR 7065 Radiator

- Designed for NASCAR and IMSA teams.

- Anodized finish for corrosion resistance.

- Factory Style Aluminum Cooling Radiator

- 1.25” core tubes for maximum flow.

- Includes brass drain petcock.

Complementary Upgrades for a Complete Track Cooling System

To maximize your radiator’s efficiency, pair it with these supporting components:

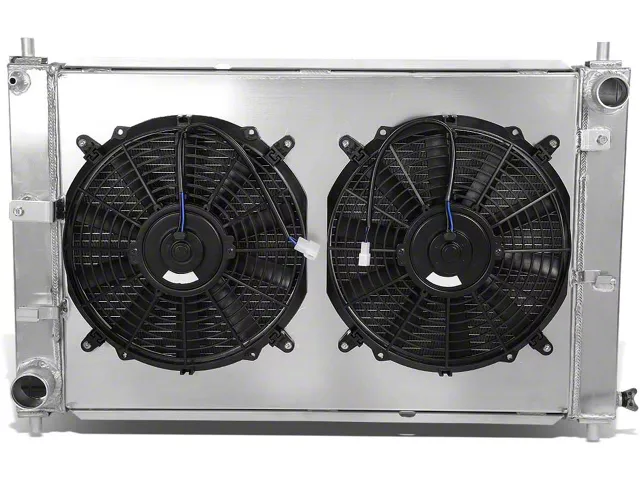

1. High-Performance Electric Fans

- SPAL Dual 12” Curved Blade Fans: 2,800 CFM airflow with PWM control.

- Derale Dyno-Cool High Performance Electric Fans: Ideal for tight engine bays.

2. Auxiliary Oil Coolers

- Setrab Series 6 Oil Cooler: 19-row core with -AN fittings.

- Improved Racing Thermostatic Plate: Regulates oil temps independently.

3. Coolant Expansion Tanks

- Moroso Aluminum Coolant Tank: Relieves pressure surges during hard braking.

- Mishimoto Catch Can Combos: Reduces coolant aeration.

4. Heat-Reflective Wrapping

- Design Engineering Titanium Exhaust Wrap: Shields radiator from turbo/exhaust heat.

- Thermo-Tec Radiator Shields: Redirects airflow through the core.

5. Upgraded Thermostats

- Motorcraft 160°F Low-Temp Thermostat: Lowers coolant activation temperature.

Installation Tips for DIY Enthusiasts

- Bleed the System Properly: Air pockets cause hot spots. Use a spill-free funnel kit.

- Upgrade Hoses and Clamps: Silicone hoses (e.g., Samco Sport) resist blowouts.

6. Maintenance and Longevity of Aluminum Radiators

A heavy-duty aluminum radiator is an investment, and proper maintenance ensures it delivers peak performance for years. Here’s how to keep your cooling system in top shape:

Flushing the System

- Annual Coolant Replacement: Use a 50/50 mix of distilled water and ethylene glycol-based coolant. Avoid universal “mixes with all colors” formulas—stick to Ford-approved Motorcraft Orange or Yellow.

- Chemical Flush Kits: Products like Prestone Radiator Flush dissolve scale and rust in neglected systems.

Inspecting for Damage

- Leak Checks: Pressure-test the system annually (15-18 PSI). Look for cracks near welds or mounting points.

- Fin Straightening: Bent fins block airflow. Use a Radiator Fin Comb to gently realign them.

Corrosion Prevention

- Anodized Coatings: Radiators like the C&R Racing Pro Series use anodization to resist oxidation.

- Cathodic Protection: Install a Zerust Capsule in the coolant tank to neutralize electrolytic corrosion.

7. Real-World Performance: Case Studies and Testimonials

Case Study 1: Endurance Racing with the CSF Triple-Pass Radiator

A 2018 Mustang GT competing in the 24 Hours of Lemons saw coolant temps drop from 245°F to 195°F after installing the CSF Racing Triple-Pass Radiator. The team reported zero overheating incidents despite 8-hour continuous sessions.

Case Study 2: Drag Strip Dominance with Mishimoto

A supercharged 2020 Mustang GT running a Mishimoto Radiator and SPAL Fans shaved 0.3 seconds off its quarter-mile time. Consistent coolant temps allowed for tighter timing advance and reduced knock.

8. Aluminum vs. Copper/Plastic: Material Showdown

Copper/Brass Radiators

- Pros: Slightly better thermal conductivity than aluminum.

- Cons: Heavy (15-20 lbs heavier), prone to solder joint failures, and expensive.

Plastic-Tank Radiators

- Pros: Cheap and lightweight.

- Cons: Plastic tanks crack under thermal cycling; unsuitable for track use.

Verdict: Aluminum’s strength, weight savings, and corrosion resistance make it the undisputed choice for track builds.

9. Advanced Cooling System Modifications

High-Flow Water Pumps

- Meziere Electric Water Pump: Reduces parasitic drag and allows RPM-independent coolant flow.

- Melling M328 High-Volume Pump: Moves 30% more coolant than stock for boosted engines.

Coolant Additives

- Water Wetter: Reduces surface tension for better heat transfer.

- Evans Waterless Coolant: Eliminates boil-over risk (boiling point: 375°F).

10. Monitoring and Diagnostics: Tools for Track Day

OBD-II Scanners

- HPTuners VCM Scanner: Log coolant temps, fan cycles, and engine load in real time.

- Aeroforce Interceptor Gauge: Displays coolant temp on a pillar-mounted screen.

Infrared Thermometers

- Fluke 62 MAX+: Spot-check radiator inlet/outlet temps for efficiency analysis.

11. Frequently Asked Questions

Q: Can I use a track radiator for daily driving?

A: Yes! Modern aluminum radiators improve cooling in all conditions without compromising reliability.

Q: Do I need a custom shroud?

A: Stock shrouds work, but a Mishimoto Fan Shroud improves airflow direction by 22%.

Q: Will a larger radiator affect horsepower?

A: Indirectly—stable temps allow for consistent power delivery, especially in forced-induction setups.

12. Top Heavy-Duty Radiators

- Be Cool Racing Extreme Radiator

- 1.5” core with stacked-plate design.

- Customizable AN fittings for dry-break systems.

- Ron Davis Racing Pro Series

- Aerospace-grade 6061-T6 aluminum.

- Handcrafted for twin-turbo applications.

- DeWitts Direct-Fit Radiator

- Internal oil cooler provisions.

- Black powder-coated finish for stealth builds.

- Griffin Thermal Products LS-Swap Radiator

- Compatible with LS-swapped Mustangs.

- Dual 1.25” cores for crossflow efficiency.

- Vibrant Performance Ultra-Cool Radiator

- TIG-welded 3” core.

- Integrated -10AN steam vent ports.

13. Complementary Upgrades

Oil Cooling Systems

- Mocal Thermostatic Sandwich Plate: Directs oil to coolers only when needed.

- Canton Racing Accusump: Stabilizes oil pressure during hard cornering.

Aerodynamic Enhancements for Optimal Cooling Efficiency

Aerodynamics play a pivotal role in managing engine temperatures on the track. Proper airflow directs cool air to the radiator while expelling hot air from the engine bay. Here’s how to optimize your Mustang GT’s aerodynamics for cooling:

1. Hood Vents

Hood vents reduce underhood pressure, allowing hot air to escape efficiently. Key products include:

- Ford Performance Hood Vent Kit: OEM-designed vents that integrate seamlessly with factory body lines.

- Anderson Composites GT4-Style Hood: Features aggressive venting for maximum heat extraction.

2. Front Splitters and Air Dams

These components channel airflow directly into the radiator. Consider:

- APR Performance GTC-300 Splitter: Redirects air to the radiator core and brake ducts.

- MMD V-Series Chin Spoiler: Enhances downforce while improving cooling airflow.

3. Radiator Ducting

Sealing gaps between the radiator and grille ensures air passes through the core, not around it. Products like:

- ZL1 Addons Radiator Seal Kit: Custom-fit foam seals for S550/S650 Mustangs.

- Track Spec Hood Louvers: Adjustable louvers that balance airflow and aerodynamics.

Transmission and Differential Cooling: Beyond the Engine

Track driving stresses not just the engine but also the transmission and differential. Overheating these components can lead to fluid breakdown and mechanical failure.

1. Transmission Coolers

- Derale 13503 Series Stacked Plate Cooler: Compact design with high heat dissipation for automatic transmissions.

- Tru Cool 4590 Universal Cooler: Thermostatically controlled to maintain optimal fluid temps.

2. Differential Coolers

- Improved Racing Differential Cooler Kit: Includes a pump, cooler, and mounting hardware for IRS-equipped Mustangs.

- Setrab Differential Cooler: 10-row core with AN fittings for custom setups.

Seasonal Maintenance for Year-Round Track Readiness

Extreme temperatures demand tailored maintenance strategies:

1. Summer Preparation

- Evans High-Performance Coolant: Eliminates boil-over risks in scorching conditions.

- DEI Reflect-A-Gold Radiator Shield: Reflects radiant heat from exhaust components.

2. Winter Considerations

- Motorcraft Premium Antifreeze: Prevents freezing while protecting aluminum components.

- FrostHeater Pre-Heater Kit: Maintains optimal coolant temps during cold starts.

Troubleshooting Common Track Cooling Issues

Even with upgrades, challenges can arise. Diagnose problems with these tools:

1. Overheating Under Load

- Checklist: Verify coolant levels, fan operation, and thermostat function.

- Tool: Autool X50 OBD2 Scanner monitors real-time coolant temps and fan cycles.

2. Coolant Leaks

- Solution: Upgrade to Silicone Hose Kits (e.g., Samco Sport) and Constant-Tension Clamps.

Balanced Cooling Systems: Synergy Between Components

A high-performance radiator alone isn’t enough. Ensure harmony between:

- Water Pump: Melling M328 High-Flow Pump for increased coolant circulation.

- Thermostat: Reische 170°F Performance Thermostat for precise temperature control.

- Coolant: Red Line Water Wetter enhances heat transfer efficiency.

Track-Specific Setups: Road Course vs. Drag Racing

Tailor your cooling system to your discipline:

1. Road Course/Endurance Racing

- Priority: Sustained cooling with triple-pass radiators (e.g., CSF Racing) and auxiliary oil coolers.

- Product: Canton Racing Accusump stabilizes oil pressure during long corners.

2. Drag Racing

- Focus: Rapid heat dissipation between runs. Use Meziere Electric Water Pump for instant coolant flow.

- Product: Moroso Coolant Expansion Tank handles pressure spikes from launches.

Debunking Cooling System Myths

- Myth: “Thicker radiator cores always cool better.”

Truth: Excessive core thickness can restrict airflow—balance fin density and fan power. - Myth: “Water Wetter replaces coolant.”

Truth: It’s an additive—always use with a proper coolant mix.

Expert Insights: Pro Tips from Racers

- Quote: “A C&R Racing Radiator with SPAL Fans dropped our temps by 30°F at Daytona.” – John P., SCCA National Champion.

- Tip: “Wrap headers with DEI Titanium Wrap to reduce underhood heat soaking the radiator.” – Sarah L., Performance Tuner.

Final Product Recommendations

Advanced Aerodynamic Upgrades

- Sparco Hood Pins: Secure vented hoods at high speeds.

- Race Louvers Custom Vents: Laser-cut designs for precise airflow management.

Specialized Tools

- OTC Cooling System Pressure Tester: Identifies leaks before track days.

- Radiator Genie Flush Kit: Simplifies coolant system bleeding.

Conclusion: Building a Track-Ready Cooling System

Your Ford Mustang GT’s track performance hinges on a robust cooling ecosystem. From selecting a heavy-duty aluminum radiator to optimizing aerodynamics and auxiliary systems, each component must work in concert to combat heat. Invest in quality parts like the Mishimoto Radiator and Setrab Oil Coolers, adhere to rigorous maintenance, and tailor your setup to your racing discipline. With these strategies, your Mustang will dominate the track, lap after lap.

“Disclaimer: As an Amazon Associate,Some of the links on this website are affiliate links, meaning we may earn a commission if you make a purchase through these links at no extra cost to you. This helps support the maintenance of the site. We only recommend products or services we believe in.”